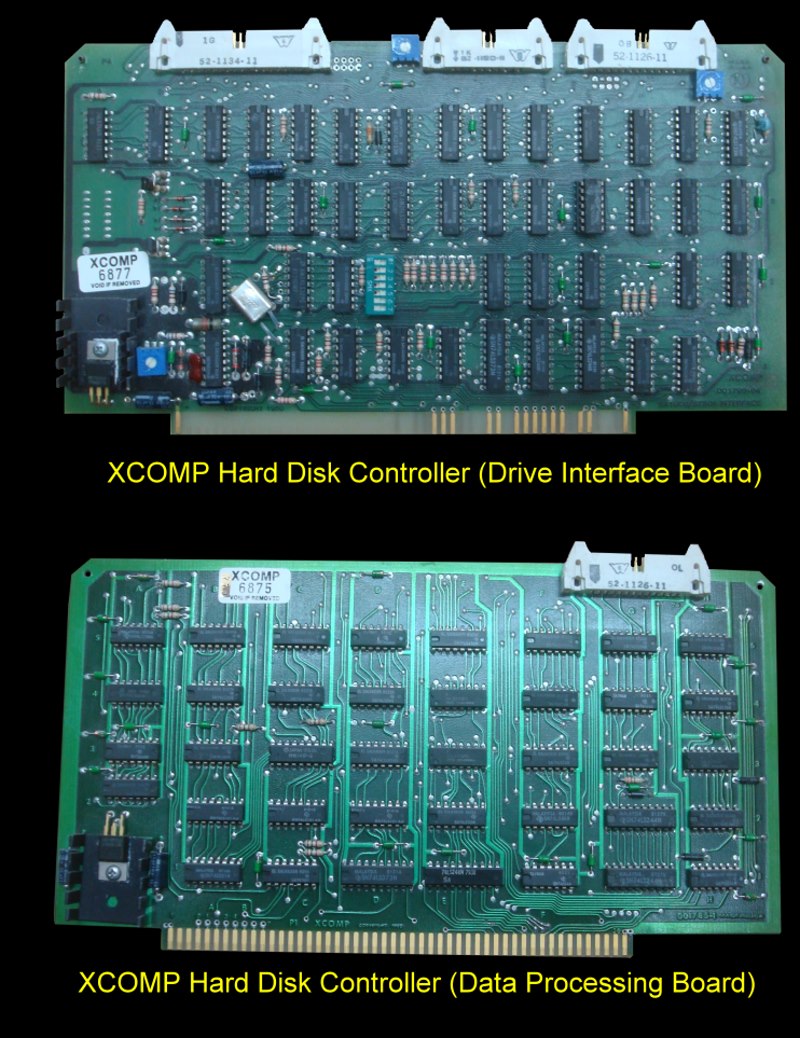

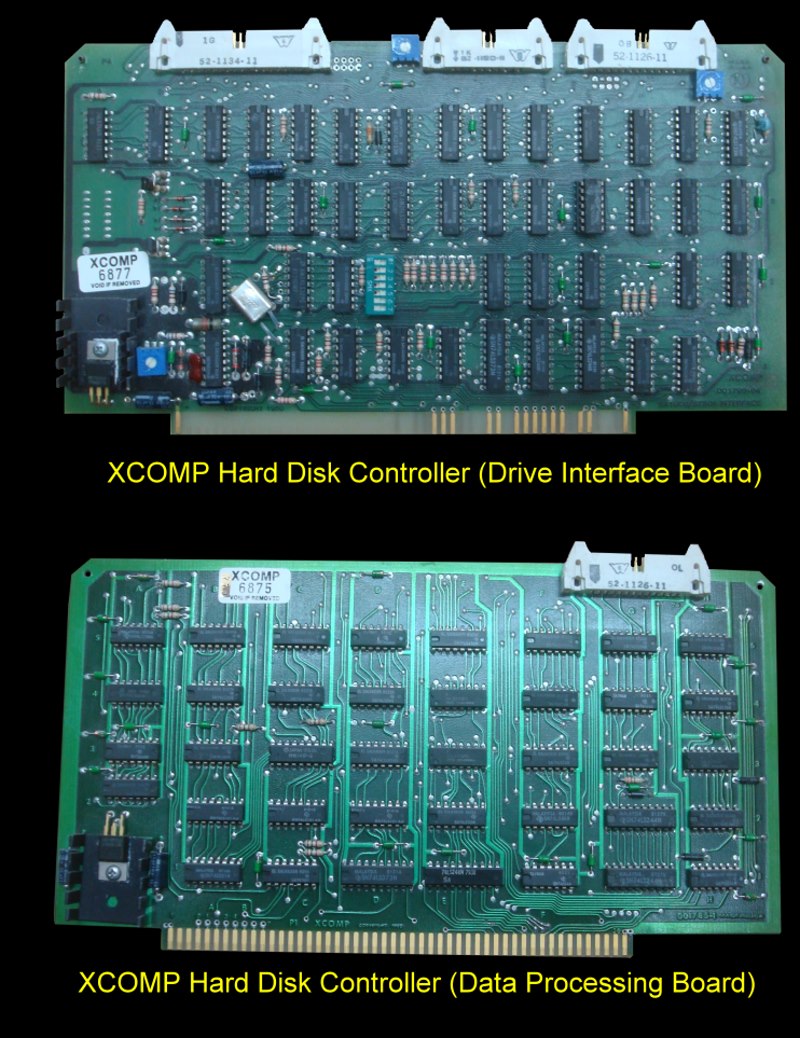

XCOMP -- Hard Disk Controller

The controller consisted of two S-100 boards connected together with a cable

at the top right of the board. One board was used to interface with

the hard disk(s) and connected to the hard disk via two cables. The other

board actually processed the data and fed it to the system CPU via

the S-100 bus.

This XCOMP hard disk controller was in fact a set of boards with a different

drive interface board for each type of drive. It featured great operating

power in a compact, two S100 PC board package. The micro-programmed data

board processing was common to all controllers and operated with a second

drive interface board. They efficiently control a wide variety of drives

including the following HD interfaces:

• SMD (Storage Module Drive

• 5440 or 2315 cartridge

• ANSI disk bus

• Shugart SA-1000

• Shugart Technology ST-500

Additional interfaces could probably also be accommodated.

The board had the following features.

• A custom micro-programmable

processor to provides high performance.

• Feature multibank writable control memory for ultimate

flexibility.

• Maximum data integrity was maintained with a separate

header field for each disk sector.

• Support software available for a number of popular

operating systems, CP/M included.

• Fault isolation software for controller testing runs on

host computer.

The key to the XCOMP controller was its custom micro-programmable processor

which controlled data transfers. Custom microcode, provided by XCOMP, was

stored in writable control memory to accommodate specific drives. This

approach generated three major advantages: easy adaptation to the myriad of

drives by changing only the I/O driver software, simplified testing of the

controller by fault isolation software run on the host computer, and very

high performance.

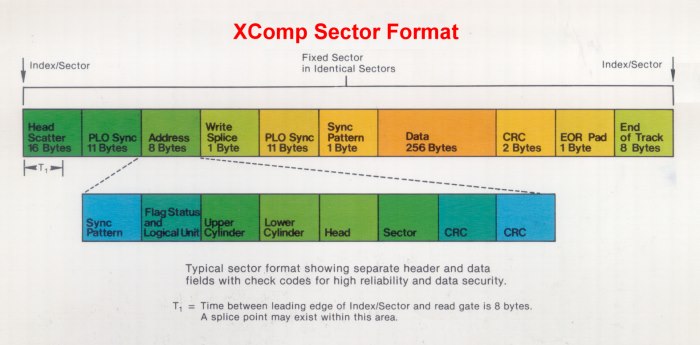

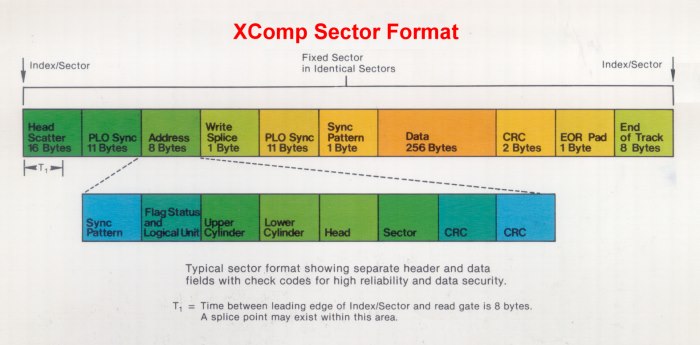

A sector format of separate header and data fields was used, each having

sync and check characters. By testing the header for correct head, cylinder

and sector before Reading and Writing on the data area, total data security

was assured without the time consuming separate Read operations to determine

correct head position. Average Read or Write operation latency time was only

one-half revolution.

These controllers use a 256 byte sector format and had a full sector buffer.

The logical sector format allowed interleaving which maximizes system

performance. The design eliminated problems with interrupt response time and

with bank switch systems under CP/M3 and MP/M operating systems. The buffer

was used in "look ahead" mode for increased system performance.

SPECIFICATIONS

• Buffer size - 256 bytes

• Disc data rate up to 10 MHz

• 8 BIT bus transfer

• Capable of 6 MHz IEEE operation on S100

• Separate header with 2 byte check code

• I/O addresses - any 8 address block on even boundary

• The board could be used in programmed I/O or interrupt

mode

• Interrupts could be jumper to any level

• Interrupts were generated on seek and/or data transfer

complete

XComp actually had 4 variations of the above boards and software. They are

referred to in the documentation as:-

SG/S If you

were using the above board with a Shugart 8" SA1000. (The extra pins on the

top left accommodated the larger cable connector. I have an SA1000 and one

day will try it out. The transparent cover where you can see the disk and

heads is real neat!

ST/S If you

are using a 5" ST506 hard disk and the above board.

They also had a ribbon cable/board arrangement where the second board was in

the disk drive rather than in the S-100 bus.

SG/S If an

8" SA1000 was used with this arrangement

ST/R If a 5:

ST506 type drive was used.

The software supplied was extensive and very well done. It's important

to realize that the data processing board has its own microprocessor that

needs to be fed specific "micro-code" to have it do something. Once these

bytes of data are sent, the board comes alive and carries out the required

function. The board is completely I/O mapped using a block of 8

ports. The default is 78H to 7FH.

XComp supplied source code to setup your system. Amongst the list was the

following Z80 programs.

SAATS Tests seek logic on the board

SAFMT Format and verify the hard disk.

SAIOS A BIOS driver for CPM V2.2

SAROM An example of a bootstrap ROM based loader

SARDT Random Read/Write diagnostic test

SARWT Read/Write diagnostic test

XSBT Test the onboard RAM buffer on the board.

I intend to extensively document this board/software in the future since it

is the basic HD board I use in my own S-100 system using CPM+, CPM-86 and

MS-DOS. This will however be a few months away. For now I am just

including the source code XComp supplied.

XComp HD Controller Files (.Zip

Format)

The sales brochure for this controller can be obtained

here.

The manual for this board can be obtained

here

The schematic for the two above boards can be obtained

here.

A short summary of XComp software can be obtained

here.

This page was last modified

on

01/08/2011